N-80和L-80套管之间的差异

ASTM A335 alloy seamless steel pipe Gr. P22, 3 inch SCH 120

2016年11月3日

API 5DP钻杆,级E75,OD 127mm,壁厚12.7mm

November 10, 2016Macaroni Tubing: 1 1/4″– 2 1/16″ Nom.

等级:J55,K55,N80,L80,P110

Specializeds:.

Threading.

热处理。

External upset.

徘徊(全长或仅结束)。

静水压试验。

完整的第三方考试能力(EMI,海, and Weld Line).

联轴器外加厚,AB修改、否认、独特的clearance couplings.

完成客户规范。

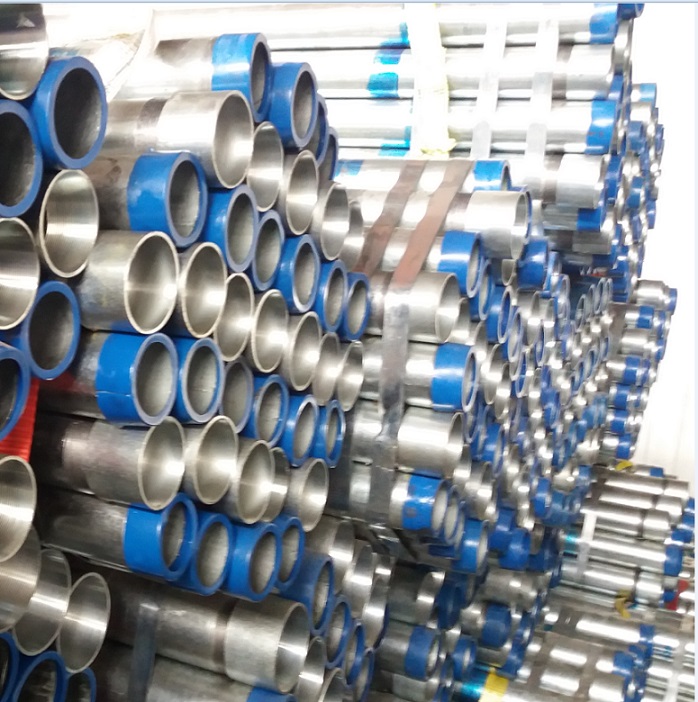

N80 Casing Pipe Description

N80 steel casing pipe is a crucial tool utilized in oil well drilling (Other important tools consist of drill pipe, core barrel, casing, drill collar, little size steel tube used in drilling, etc.). This casing tube is made from steel of N80 grade. It is used for reinforcing the well wall. It is likewise a tunnel that provides petroleum from underground to surface area. This item is a completion tool used after the drilling procedure and in the past well cementation.

1. The thread and coupling of this steel casing pipe are specially processed which have smooth surface area without any burr, tear or other flaws. These defects might have a bad influence on the products’ strength and connection.

4.该管的尺寸可区别于41/2“至20”。所有管道均严格按照API要求生产。

N80钢套管是油井钻井中使用的必备工具(其他关键工具包括钻杆,芯桶,套管,钻套,小尺寸钢管,用于钻孔,等等)。该钢套管的螺纹和耦合是专门加工的,具有光滑的表面积,没有任何毛刺,撕裂或其他问题。

API-5CT N80套管contains N80-1 and N80-Q types. Those 2 products are definitely consistent concerning the chemical structure and mechanical attributes, they are simply different in the heat treatment.

在整个热处理中,通过稳定和回火处理N80-1钢,而N80Q钢通过淬火和回火处理。因此,N80Q的塌陷强度和内部压力强度大于N80-1的强度。当挑选N80套管时,设计人员应该清楚地显示N80-1或N80Q。

由于其机械性能高于J55和K55类型,因此可能真的很好地利用了某些更具挑战性的发展。井下井下深度比J55和K55类型更深入,可以要求利用中级油气和天然气。

Due to the high ability of N80 product, those API-5CT casing pipes are broadly used in gas as well as coal bed methane extraction, and geothermal wells.

规格

| Material: | L80, steel grade |

| 外径: | 4 1/2“-20”,(114.3-508mm) |

| Wall Thickness: | 5.12-16.13mm. |

| 线程类型: | 支撑螺纹外壳,长圆形套管,短圆形套管 |

| 功能: | 它用于保护管道。 |

参数

| 组 | 钢级 | Type | 碳 | 锰 | Molybdenum | Chromium | 镍 Max. |

Copper Max. |

Phosphorus Max. |

Sulfur Max. |

Silicon Max. |

||||

| 分钟。 | Max. | 分钟。 | Max. | 分钟。 | Max. | 分钟。 | Max. | ||||||||

| 1 | 2 | 3. | 4. | 5. | 6. | 7. | 8. | 9. | 10. | 11. | 12. | 13. | 14. | 15. | 16. |

| 2 | L80 | 1 | - | 0.43 | - | 1.9 | - | - | - | - | 0.25 | 0.35 | 0.03 | 0.03 | 0.45 |

| L80 | 9CR. | - | 0.15 | 0.3 | 0.6 | 0.9 | 1.1 | 8. | 10. | 0.5 | 0.25 | 0.02 | 0.01 | 1 | |

| L80 | 13CR. | 0.15 | 0.22 | 0.25 | 1 | - | - | 12. | 14. | 0.5 | 0.25 | 0.02 | 0.01 | 1 | |

| Any product is subject oil quenching process above, the upper limit of the carbon content of L80 steel grade can be increased to 0.50%. | |||||||||||||||

API 5CT L80石油套管是保存油井运行的生命线。除了地下动态之外,地质条件也是多种多样的。管道在许多力下被指定,例如拉力,压力,弯曲力和扭转张力。在这种情况下,必须对套管管道进行显着质量的需求。在任何故障的情况下,诸如生产扰动或良好终端的毁灭性结果是不可避免的。