- HEBEI SCHREIBEN STEEL PIPE CO., LTD.

- 86-317-3736333

- 86-317-2011165

- abter2016@163.com

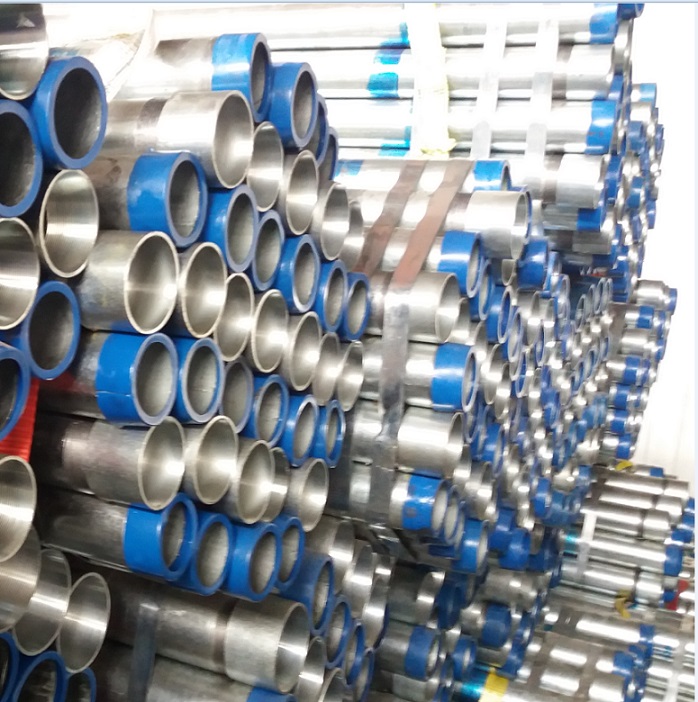

Keramik-gezeichnete Rohr

Außenbeschichtung

February24, 2017Epoxy beschichtet

February24, 2017Keramik-gezeichnete Rohr

Keramik-gezeichnete Rohr ist der Einsatz von SHS – Herstellung von Zentrifugation, der Schmelzpunkt von Aluminiumoxid Keramik Rohr in 2045 ℃, Aluminiumoxid-Schicht und der Stahl Schichtaufbau aus besonderen Gründen Prozess, das Spannungsfeld ist auch etwas besonderes. Bei Raumtemperatur Keramikschicht Druckspannung, Zugspannung von Stahl Schicht, die beiden Gegensätze, in einem ausgewogenen ganzen. Nur die Temperatur steigt über 400 ℃, sowohl wegen der thermische Ausdehnungskoeffizient ist nicht das gleiche, Das neue Spannungsfeld erzeugt durch die Wärmeausdehnung der Keramik und Stahl im Beisein der ursprünglichen Belastung Feld abbrechen einander,so that both the ceramic layer and the steel layer is in free equilibrium.When the temperature rises to900℃ Ling ceramic lined steel pipe placed inside the water,repeated immersion times,the composite layer does not crack or split,showing ordinary ceramic unparalleled thermal shock resistance.This performance in the construction of great use,because of its outer layer is made of steel,coupled with the inner temperature does not crack in the construction of the flange,purge port,explosion-proof doors can be welded directly to the welding method can also be used connection,than wear and cast stone pipe,wear steel pipe,wear-resistant steel rare,double metal composite pipe, Stahlrohr,steel rubber tube in the construction can not be easily welded or soldered better.Ceramic Lined resistance to mechanical shock resistance or,in between the transportation,installation and beat two brackets weight bending deformation,not broken off the composite layer.

Ceramic-lined pipe with traditional steel,wear-resistant alloy steel pipe,铸石和钢塑管,steel pipe and other rubber has essential difference.Ceramic outer layer is steel pipe inner corundum.Corundum layer up to100-1500 Vickers-Härte (Rockwell hardness of90-98),the equivalent of tungsten-cobalt hard gold.High wear resistance thanc-Stahl Rohrmehr als 20 mal,it is much more superior than the usual adhesive wheel made of corundum performance.Now is still a variety of corundum grinding wheel grinder cut hardened steel main wheel.Ceramic pipe layer in the corundum corundum grinding wheel wear out.Wear-resistant ceramic pipe corundum mainly by a few millimeters thick inner layer,the Mohs hardness of9,second only to diamond and silicon carbide,oxide in all,it is the highest hardness.

Ceramic-lined pipe with high wear resistance,anti-erosionability fluid.In a wind pipe,pipe wear fastest,ceramic-lined steel pipe elbow thick abrasion wear resistance than steel elbow is more than5 mal.