- ХЭБЭЙ300КМСТАЛЬНОЙТРУБЫ,ООО

- 86-317-3736333

- 86-317-2011165

- 一个bter2016@163.com

СВАРНЫЕСТАЛЬНЫЕТРУБЫVSБЕСШОВНЫХСТАЛЬНЫХТРУБПРОДУКЦИИИЗНАЧИТЕЛЬНЫХПРОЦЕССОВ

ASTM A513тип1низкоуглеродистойсталитрубки

октября 31, 2017

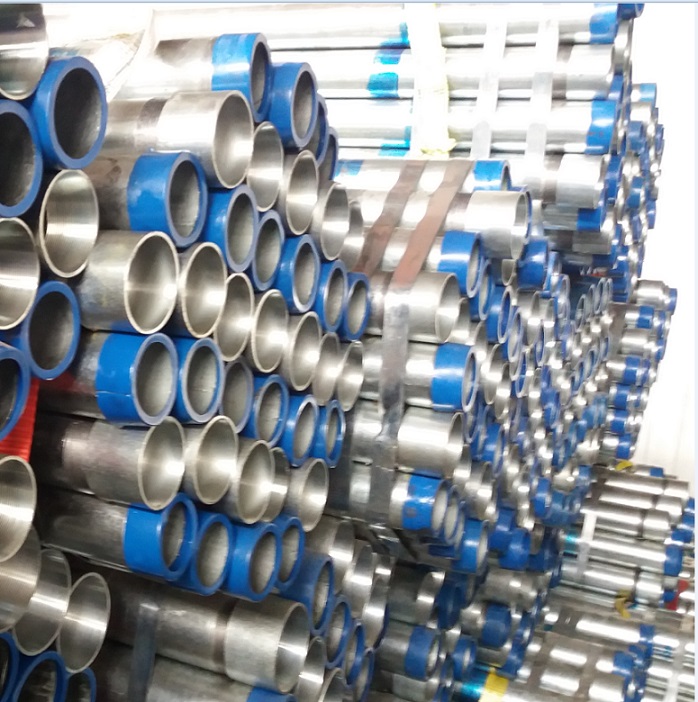

Труб для нефти и газа

Декабрь15,2017年1.0产品和重大PROCESSES:

1.1产品在这个档案勾勒出是目前由标题即认可。部门手册钢管,ТРУБЫ与配件然而其特别实用程序识别喜欢用于输送水,Газ,空气蒸汽等。,for use in basic purposes,for General Engineering purposes and so on。Funnels of different materials,(например,Чугун,ПВХ,HDPE,水泥混凝土等。)或具有不同的效用像氧叉甚至一些其他槽钢,course pipe utilized for insurance of electrical wiring framework and so on have been kept out of the domain of this manual。

1.2有关此共同管理他们的装配标准项目的理解形成伴随说明注(ссылка1.3 1.5в下)和措辞(ссылка。2.0)一个s depicted in various norms under thought including those characterized at IS1956年(铂。VIII)-1976 (术语词汇与钢铁识别:钢管)一个nd IS812 - 1957年(Glossary of terms identifying with Welding and Cutting of Metals)一个s well as Metals Hand Books distributed by American Society for Metals would demonstrate helpful。

1.3接钢管PROCESSES

在此过程中纵向成帧室(说板外,skelp,уровень,strip,板等。)通过像形成在纵向折痕被接合: -

一个)Электрическая сварка (ВПВ) –它利用业务的发展,in the first the level moved steel is chilly molded into tubular shape。Welding is affected by the use of weight and warmth produced by enlistment or by an electric flow through the crease。焊接重量通过紧固辊和高焊接电流的电磁影响创建。电气保护焊管项目损失ngitudinal crease are generally made in sizes from3.2ммдо

0.6m genuine outside distance across,however bigger sizes are additionally produced。

б)Furnace Butt Welding-In heater butt welding,制管钢板具有正方形或侮辱性倾斜边缘是加热器加热到焊接温度。The warmedсклад被辊成帧为圆和空心形状,因为它上升塑造加热器,额外的温暖通常由氧气或空气飞给定撞击折痕边缘和管经过订约辊,其中折痕边,通过轧辊的重量被焊接。加热器对焊的产品在普通直径接近3.2ммдо100 мм.

с)熔焊-In this procedure the level moved steels with edges reasonably arranged,is framed into tubular shape either by hot or cool forming。水平移动的钢可能会形成纵向(直线折痕)或扭曲成螺旋状的纵向(winding welded)。边缘是

在液体或液体和蒸气状态有或没有同时保持所有的填料金属焊接。机械重量不需要焊接的影响。组合可能是由任一电圆形段或气体加温或由两者的混合是专家。

1.4无缝钢管工艺

通过一致的程序交付钢管项目在距离跨大部分高达作出0.66米通过旋转穿透技术和高达1.22m by hot expulsion。

一个)Rotary Piercing-In revolving penetrating,重要的宽度和长度的轮首先升温至移动温度。每个热轮被维持成具有交叉战斧和表面形式的力它通过移动辊的布置,一个long these lines bursting it longitudinally。The power of the moves at that point makes the metal stream around a penetrating point,放大的枢转开口,smoothing within surface and framing a tube。Subsequent to being penetrated,不愉快的管通常被热移动到确凿测量。

б)Press Piercing-A press puncturing plant is made out of three essential components:一招仍与一对夫妇从动辊之间的轮去;钢坯推;一个nd a settled fitting situated between the two rolls。钢坯,包含在四侧管理,一个constrained against the attachment by the joined activity of the pusher and the determined rolls。该材料在扭曲压缩基本上在此过程中先天,低延长(1.2%greatest)因此坯料材料(老式的或不断投)不经受高弹性焦虑。In the wake of being punctured,the harsh tube is hot moved to definite measurement。

с)热挤压是使凹陷热工序,适当处理成一致的和不可预测的帧的管的处理完成,by compelling hot,prepierced billets through a reasonably molded hole shaped by an outer bite the dust and interior mandrel。